Simulation

Simulations have made it possible to reduce the number of trial and error tests significantly in many cases even replacing them all together.

Today simulations are part of the standard workflow, qualifying designs and products from the development phase to the production cycle . Simulations can be used to qualify and asses the process, tool and material.

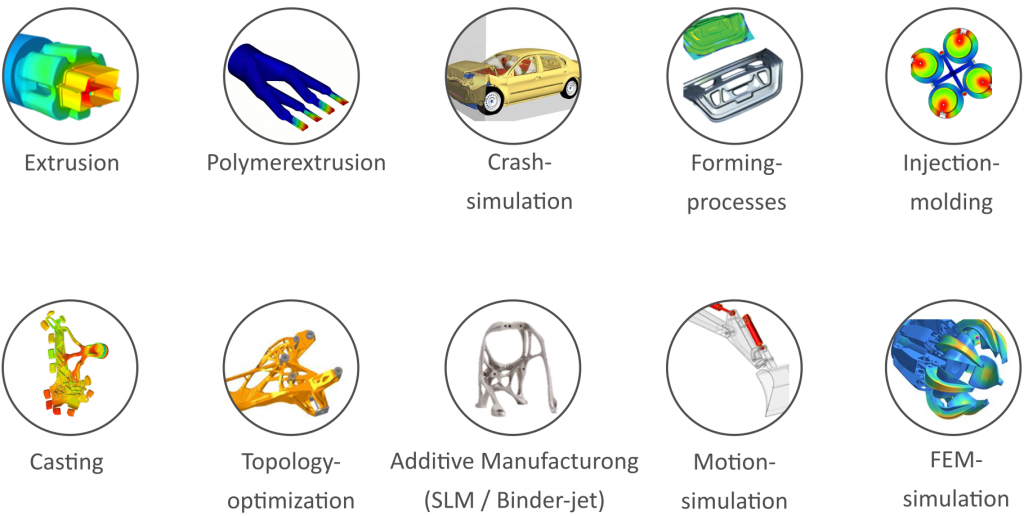

ISPT offers its service in nearly all simulation areas, from our core competency of modeling and simulation of extrusion and forming processes to CFD, injection molding and simulation of polyurethane foams.

Our own software and the the access to software solutions from Altair Engineering and Partners enable us to choose from a wide variety the optimal solution to satisfy customer demand and expectation.

Results from simulations are in many cases not exclusive to the initial problem an can be applied to other processes, thus enhancing their value even more.

Simulations enable the customer to see what happens inside the tool, to understand and to optimize the performance to enhance profitability and tool life.