Producing aluminum extrusions of the highest quality with a complex geometry is an ongoing challenge for tool manufacturers and extrusion companies. Uniform product quality from a safe and robust process is challenged by the complex interaction between geometric, process and material dependent characteristics.

The optimization of tool and process has to take all these factors in account.

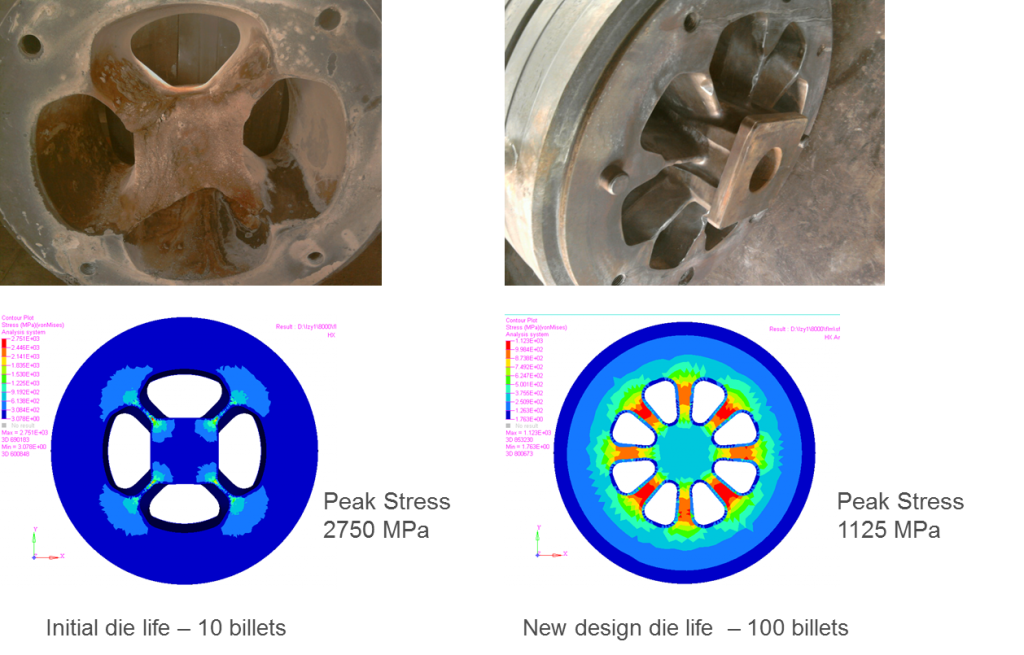

The use of 3D simulations which cover the whole process from start to finish even over multiple cycles enable us to gather the information necessary to optimize tool geometry and process parameters.

- Increased tool life

- Increased surface quality

- Increased productivity

- Reduction in test pressings

- Reduction in die deflection and distortion

- Reduzierung von Ausschuss durch kürzere Querpressnähte

- Reduction in distortion during quenching

The optimization of a extrusion process is always a business case.