Altair Inspire Mold is a fully integrated simulations suite covering every phase of the injection molding process from injection to packing, cooling and warpage. With Inspire Mold you asses the manufacturability in the earliest stages of the RFQ phase.

With its extensive integrated material database and optional access to Altairs Material Data Center the search for the matching material model is a thing of the past.

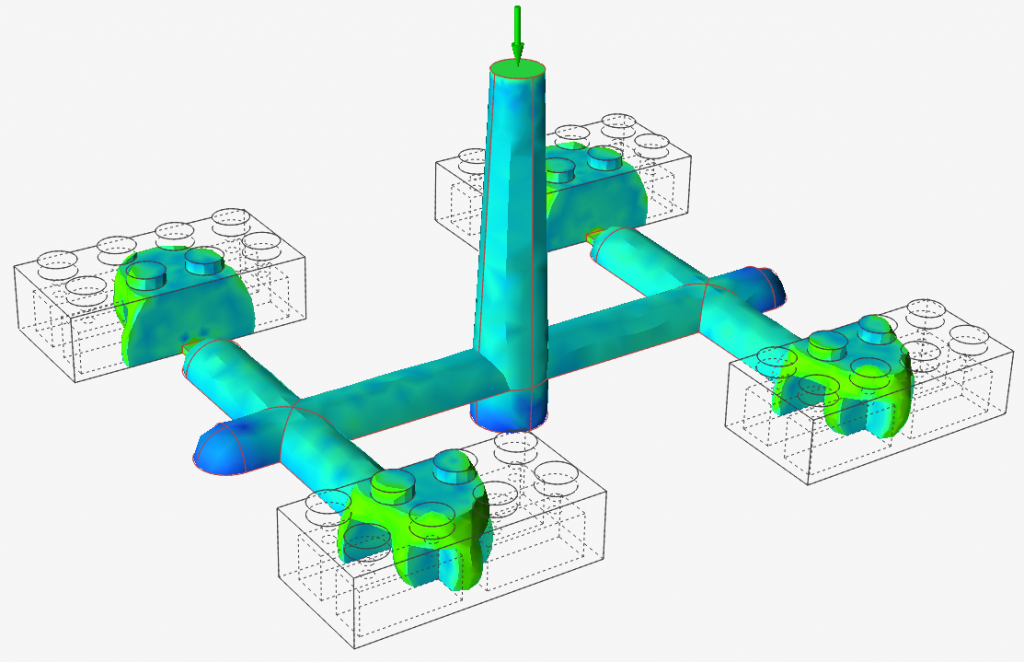

Altair Inspire Mold supports cold or hot runners und aids the user with automated functions to generate injection points, sprues, gates and supporting geometry. Simulation of the mold, user defined cooling channels, easily generated in Inspire Mold or imported from CAD the solution offers the user maximum flexibility.

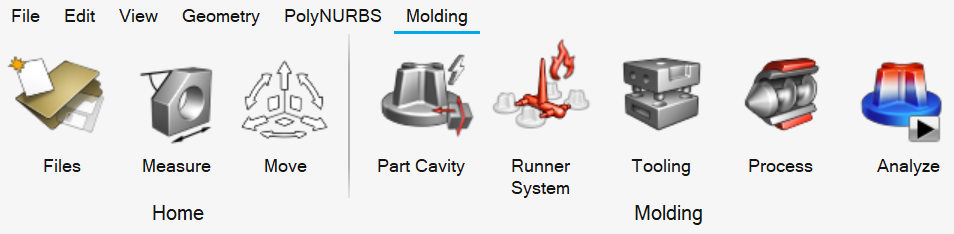

Intuitive user interface

The intuitive user interface and the automatization of laborious modelling tasks makes Altair Inspire very user friendly. Integrated tutorials and Altair’s unique online learning resources make otherwise mandatory expensive trainings dispensable thus increasing return of investment for the company.

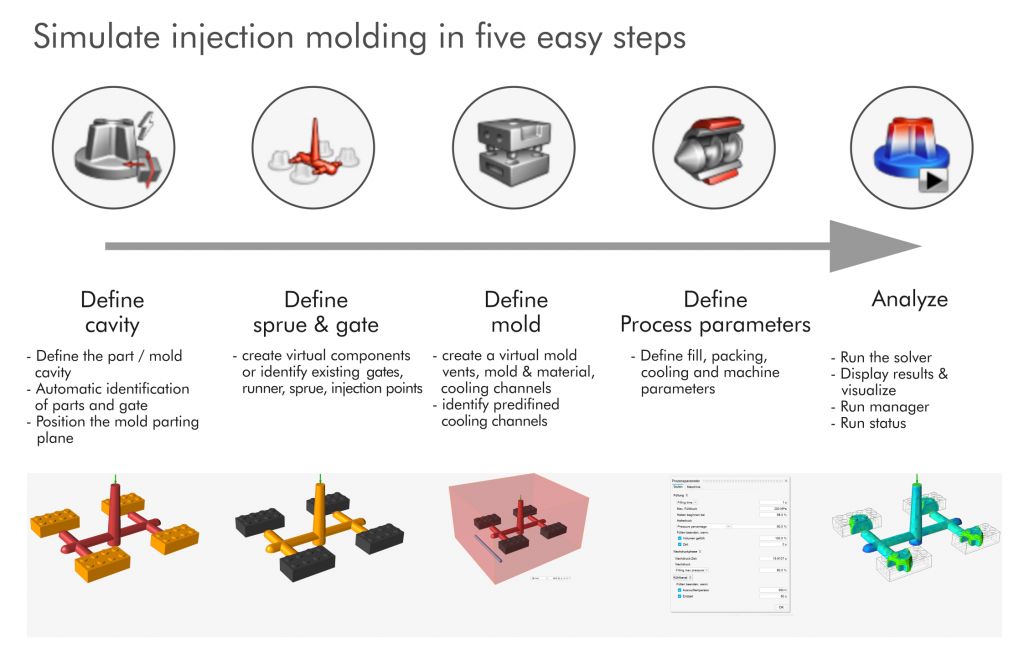

With Inspire Mold you can setup your simulation in five easy steps.

- Import / generate the part

- Definition of gates and sprue

- Tool definition and setup

- Simulation setup

- Solver run & analysis

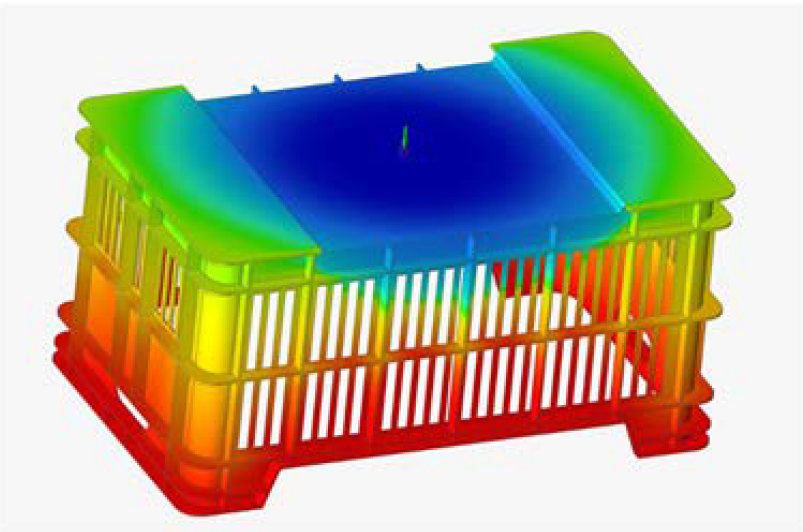

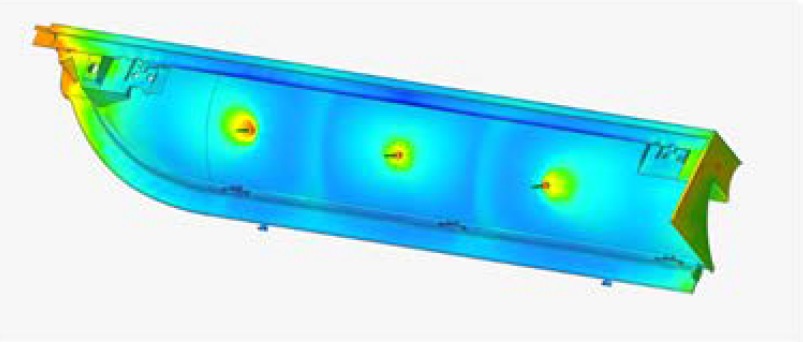

Intuitive display of analysis results

| Results filling | Results packing | Results warpage | Results cooling |

| Temperature | Temperatur | Warpage | Air pressure / Inclusions |

| Velocity | Velocity | Filling time | |

| Pressure | Pressure | ||

| Filling time | Density | ||

| Air | Sink marks | ||

| Weld lines | Tool temperature | ||

| Velocity max. | |||

| Fiber orientation | |||

| Tool temperature |