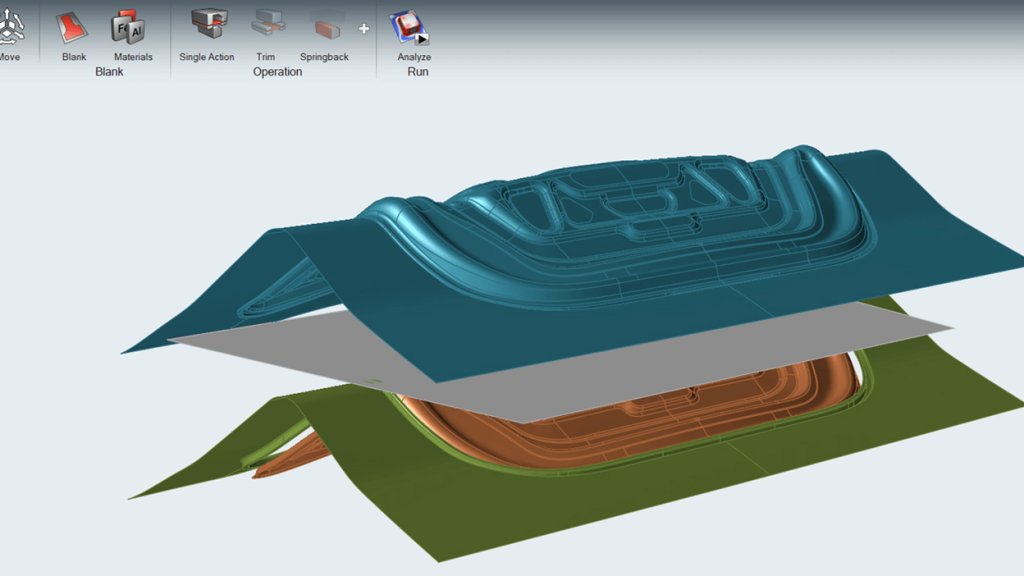

Altair Inspire Form is a comprehensive sheet metal forming simulation solution which is used by designers and process engineers alike to fast and reliably simulate forming processes. With Altair Inspire Form you can save time, material usage and costs while improving process profitability.

Altair Inspire Forms modular approach empowers you to answer questions right in the RFQ phase. The intuitive user interface and the integrated die designer make it easy to run a feasibility analysis in the earliest phases of the development process.

In the later phases of development the automated layout system can optimize material usage on the sheet and coil. The highly scalable incremental solver enables you to simulate multi-step forming processes incorporating springback compensation and trimming.

Analysis / simulation

Very fast feasibility analysis in the RFQ phase

with Altair’s one step solver

Process planning in the RFQ phase:

The results of a multi-step simulation can be utilized

Improved material usage

Automatic blank layout

Springback compensation

Improved accuracy due to springback calculation

Fast and acurate solver

Solving speed depends on the model

minutes – hours

Import of all major filetypes

- ACIS (.sab, .sat)

- CATIA V4 (.model); CATIA V5 (.CATPart .CATProduct)

- IGES (.iges, .igs)

- Inventor (.ipt, .iam)

- JT (.jt); Parasolid (.x_b, .x_t, .xmt_bin, .xmt_txt)

- Pro/Engineer (.asm, .prt)

- SolidWorks (.sldasm, .sldprt)

- STEP (.step, .stp)

- UG NX (Unigraphics) (.prt)

- Evolve PolyNURBS (.pn)