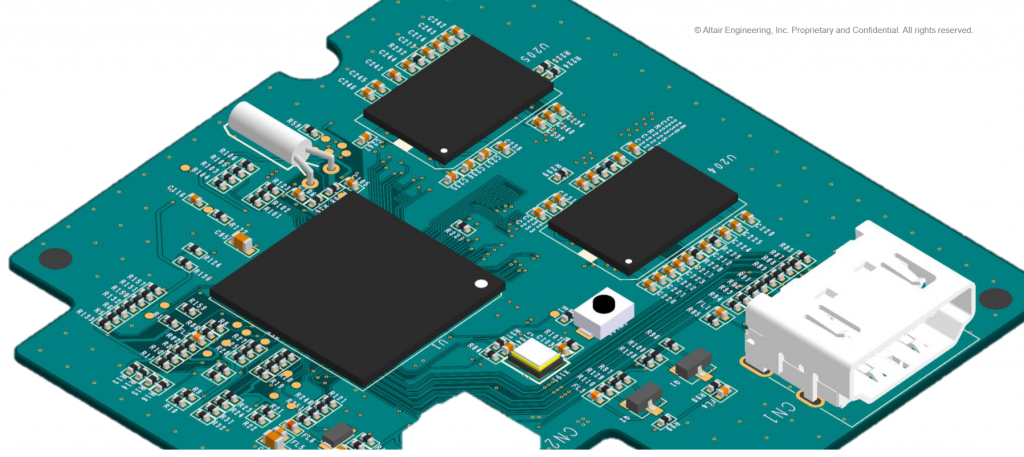

Altair PollEx is a PCB-level Electronic Design Automation (EDA) software suite covering design review,

analysis and manufacturing. It significantly reduces development cycles while providing a common communication

application between schematic engineers, PCB designers, CAE analysts, and manufacturing engineers.

PollEx can import designs from different major ECAD vendors, such as Cadence, Mentor Graphics, Zuken and Altium, as well as industrial neutral formats like ODB++ and IPC2581. Using the imported PCB design, PollEx supports verification of design for manufacturability (DFM), design for assembly (DFA), and design for electrical engineering (DFE), along with analyses (SI and thermal).

Product Highlights

- Product Highlights

- Easy-to-use collaborative application to quickly visualize and review PCB designs

- Unsurpassed connectivity to major ECAD systems

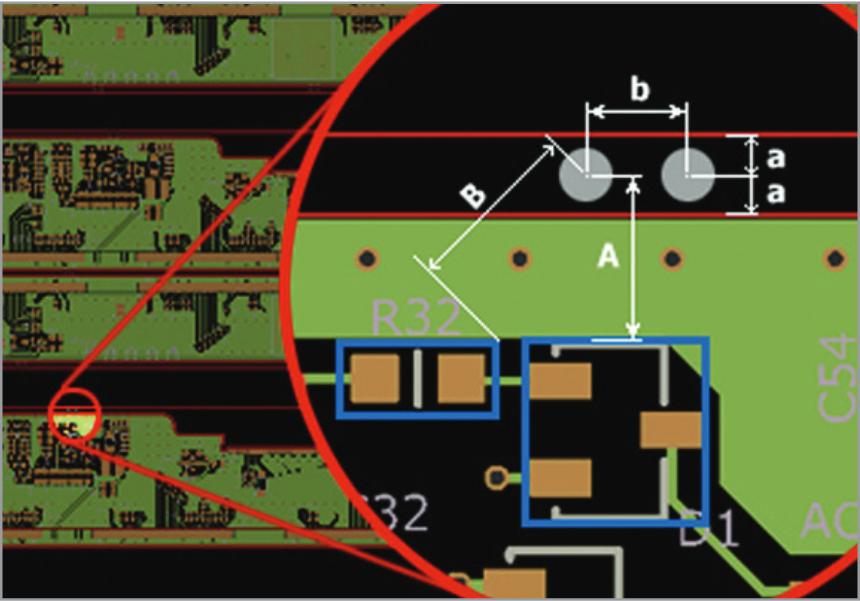

- Powerful rule-based checking tools (DFM, DFA and DFE) to detect faults early in design

- Easy solution for SI and thermal analysis of PCBs using the integrated parts and material libraries

ECAD Design Review

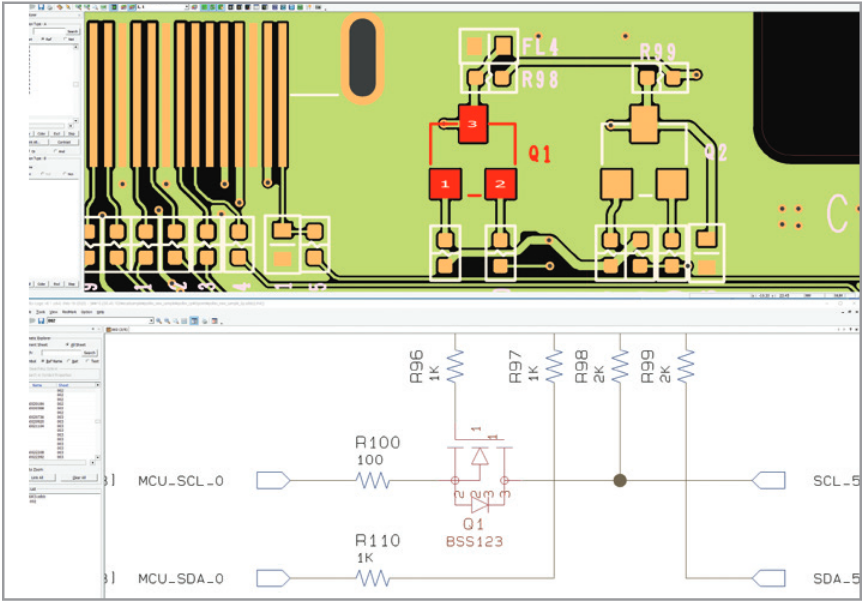

- Schematic design review from all major EDA vendors

- Gerber (274D, 274X) data review

- PCB design review from all major EDA ECAD vendors

- Comparison between PCB-to-PCB and schematic-to-schematic designs

- Comparison among PCB, schematic and BOM

- Artwork/physical/composition layer view, query, search, and measure for PCB objects

- Part, net, pad stack and via library

- Save arbitrary design shapes under a different name with a reduced file size, with a password

- Red-Mark (+) feature for comments

- Net 2D/3D display, net topology display and automatic composite net generation

Easily and automatically review and compare PCB designs using PollEx PCB Modeler

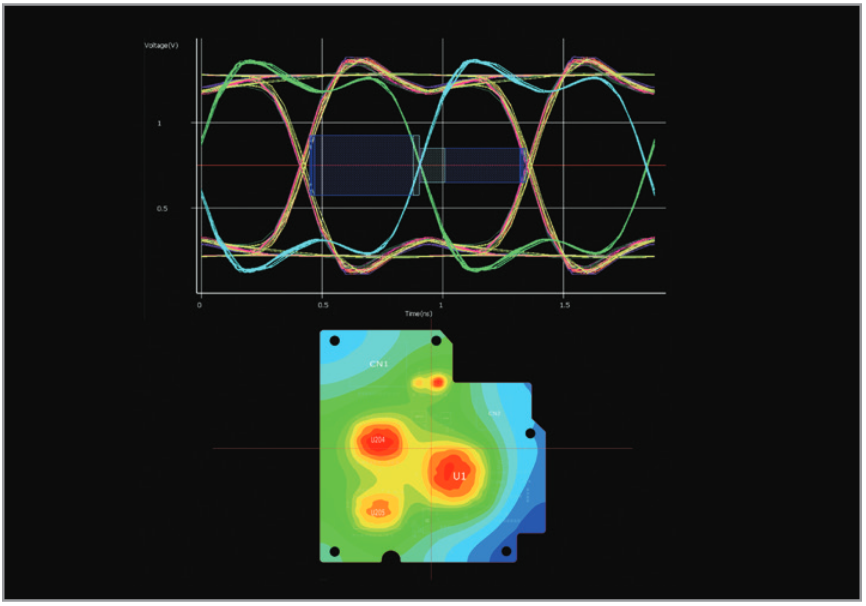

Analysis of signal integrity and thermal problems via PollEx Solvers

Verification – DFM, DFE and DFA

- Checking items for DFM (500+), DFE (300+), DFA (50+) and DFE+ (50+)

- DFM covers the manufacturing areas of board, component, drill, FPCB, package, pad, pattern, placement, and tooling.

- DFE covers the electrical areas of high-speed

signals, differential pairs, common nets, power, filters, components, and boards. - DFA covers the manufacturing assembly areas of collision, lead, placement, component and board.

- DFE+ provides verification linked to solvers

for signal integrity and thermal analysis. - Export customized and formatted Microsoft® Excel® reports of verification results.

Analysis – Signal Integrity, Thermal

- Built-in material library

- Signal integrity:

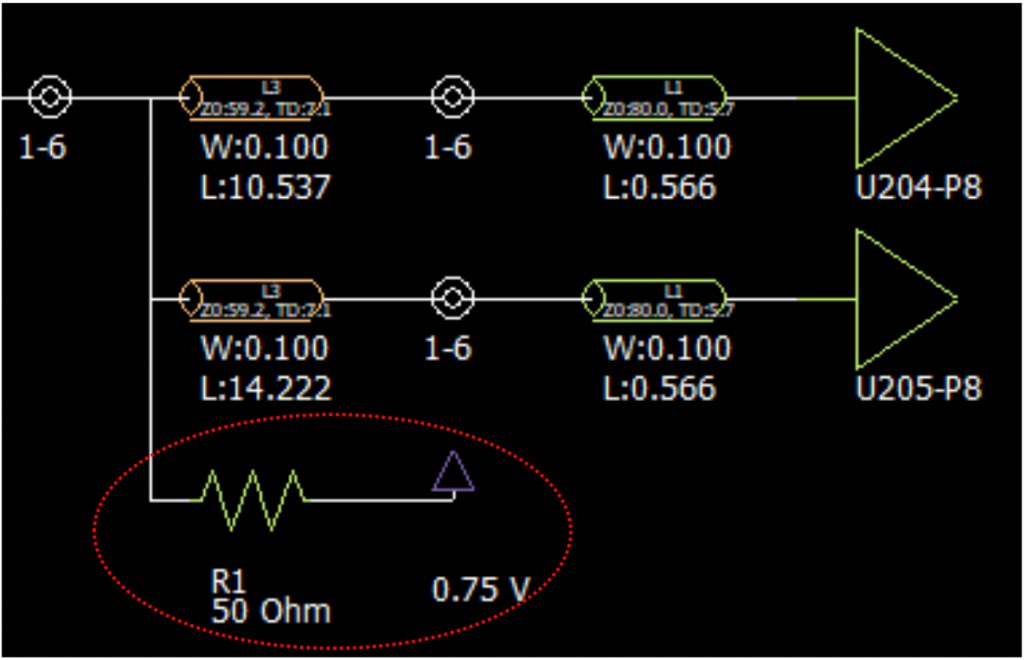

- Transmission line analysis – TML analysis and trace optimization

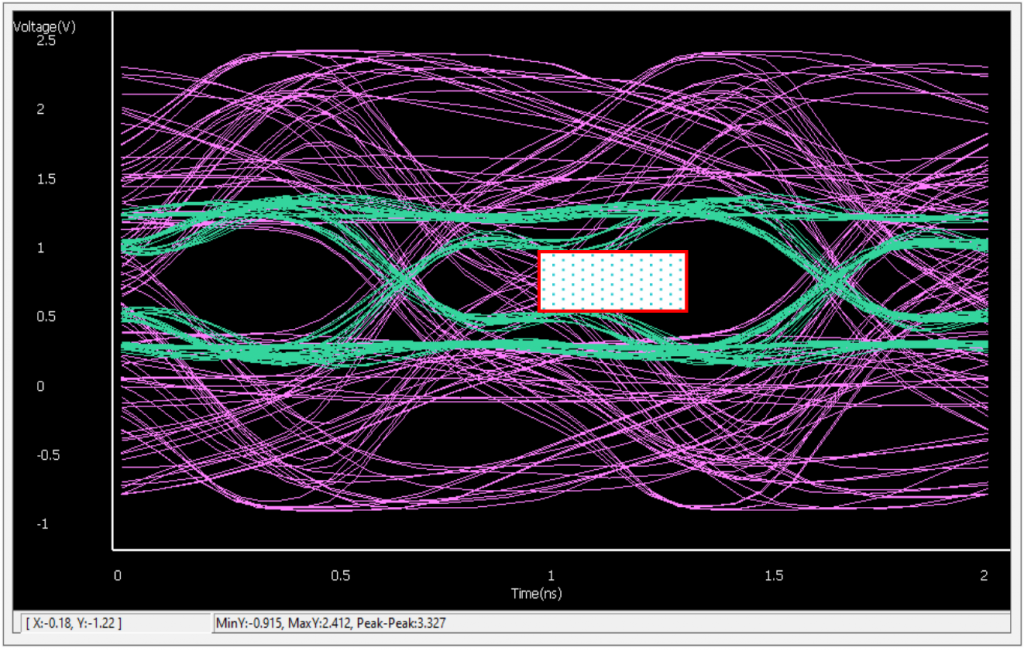

- Network analysis – Waveform analysis, eye diagram analysis, and network parameters (RLCG)

- Crosstalk analysis

- Net topology analysis, including topology editing function

- Thermal:

- Built-in package-dependent thermal resistance values for components

- 3D finite element steady-state analysis

results for thermal board contour, board top/bottom, and component junction temperature

Savings in ECAD licenses

Maximize work efficiency through improved communication among engineers from different disciplines making the same product. PollEx PCB Modeler aids better quality products by sharing schematics, PCBs and Gerber files without the need for expensive ECAD licenses.